Are you looking for a way to drill holes that are faster than a traditional drill press? Look no further than our list of the 5 best jet drill presses! Get ready to drill holes faster than ever before!

Are you looking for a new tool to add to your workshop? Look no further than the jet drill press! This powerful tool is designed for precision drilling, making it the perfect addition to any workshop.

With its powerful motor and adjustable speeds, you can get the perfect cut every time. Plus, its adjustable depth stop ensures that you won’t over-drill and ruin your project.

The jet drill press also features a quick-change chuck that allows you to quickly switch between bit sizes. This makes it easy to work with a variety of materials and sizes. Plus, the adjustable table allows you to work with larger materials and projects.

The jet drill press is the perfect tool for anyone looking to take their workshop to the next level. With its powerful motor and adjustable speeds, you can get the perfect cut every time and its adjustable depth stop ensures that you won’t over-drill and ruin your project. Plus, its quick-change chuck and adjustable table make it easy to work with a variety of materials and sizes.

If you're looking for a powerful, precise tool for your workshop, the jet drill press is the perfect choice. This powerful tool will make any project easier and faster, and it's sure to be an essential part of your workshop for years to come. Get ready to take your projects to the next level with the jet drill press!

Are you looking for a jet drill press that will give you the power and precision you need? With so many different models and brands available, it can be hard to know which one is right for your needs.

The good news is our team of experts has read thousands of reviews on Amazon to find the best jet drill presses for your needs. We've done all the hard work so that you can easily find and purchase the perfect drill press for your workshop.

No more guesswork. No more wasted money. Just the perfect jet drill press for your projects. Check out our reviews of the best jet drill presses today and get ready to take on any project with confidence!

Why We Love It:

The Jet 716000 JWDP-12 Drill Press is the perfect tool for all your drilling needs! This powerful and portable drill press is equipped with a 1/2 hp induction motor that is powerful enough to tackle the toughest jobs, and the x-shaped xacta laser ensures drilling accuracy.

It also has an impressive 10 x 16-1/8 inch cast iron base that fits perfectly on work benches with limited space and a mechanical variable speed drive system that allows for easy speed changes.

What You Should Know:

The Jet 716000 JWDP-12 Drill Press is the perfect combination of power, portability, and accuracy.

Whether you're working in the shop or on the go, the all-new Jet 12 Drill Press has you covered. Its compact bench top design allows for easy transport and the heavy-duty 1/2 hp induction motor allows for various drilling applications.

Plus, the stable base design allows for easy re-positioning on the workbench. Get your own Jet 716000 JWDP-12 Drill Press today and make all your drilling projects a breeze!

Why We Love It:

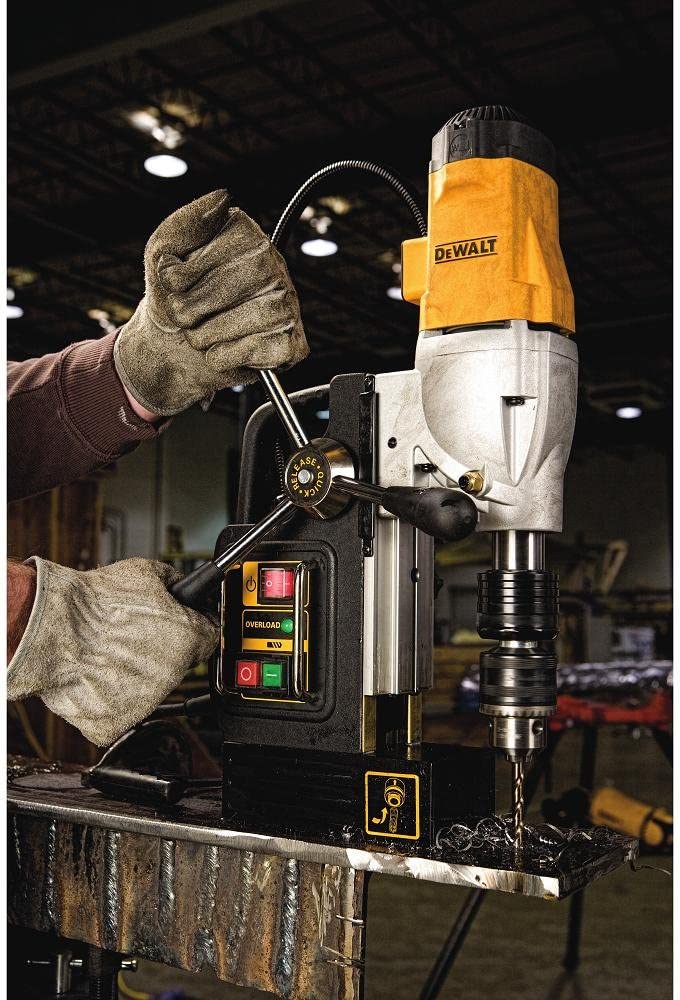

The DEWALT DWE1622K 2" 2-Speed Magnetic Drill Press is the perfect tool for any project requiring precise and accurate drilling. The 10 amp motor provides plenty of power for heavy duty applications, while the 2-speed settings give you the control you need for a variety of applications.

The Quick Change chuck system makes it easy to change out drill bits quickly and efficiently. Plus, the magnetic coolant bottle can be placed on either side of the tool or on a work surface for maximum convenience.

What You Should Know:

For those needing maximum capacity for heavy duty applications, the 4" Drill travel provided by DEWALT is the perfect solution.

And with overload protection electronics built in, you can be sure that your drill press is designed for long life. For those looking to take their drilling projects to the next level, the DEWALT DWE1622K 2" 2-Speed Magnetic Drill Press is the perfect tool for the job.

Why We Love It:

The WEN 8-Inch 5-Speed Drill Press is a great way to get maximum accuracy with your drilling projects. Featuring a 2.3A induction motor, an 8-inch swing, and a 2-inch spindle travel, you'll be able to make precise and precise holes in a variety of materials like wood, plastics, and metal.

Plus, with its five operating speeds ranging from 740 to 3140 RPM, you can adjust the speed to the exact speed you need for the job.

What You Should Know:

Not only is the WEN 8-Inch 5-Speed Drill Press great for precision and accuracy, it also includes a 1/2-inch keyed chuck for easy bit changing and onboard key storage for easy access. It also features a 6.5 by 6.5 inch adjustable worktable that bevels up to 45 degrees in each direction.

And it's conveniently sized at only 23 inches tall with a 7 by 11-inch base, making it perfect for small workspaces. So why wait? Get your own WEN 8-Inch 5-Speed Drill Press today!

Why We Love It:

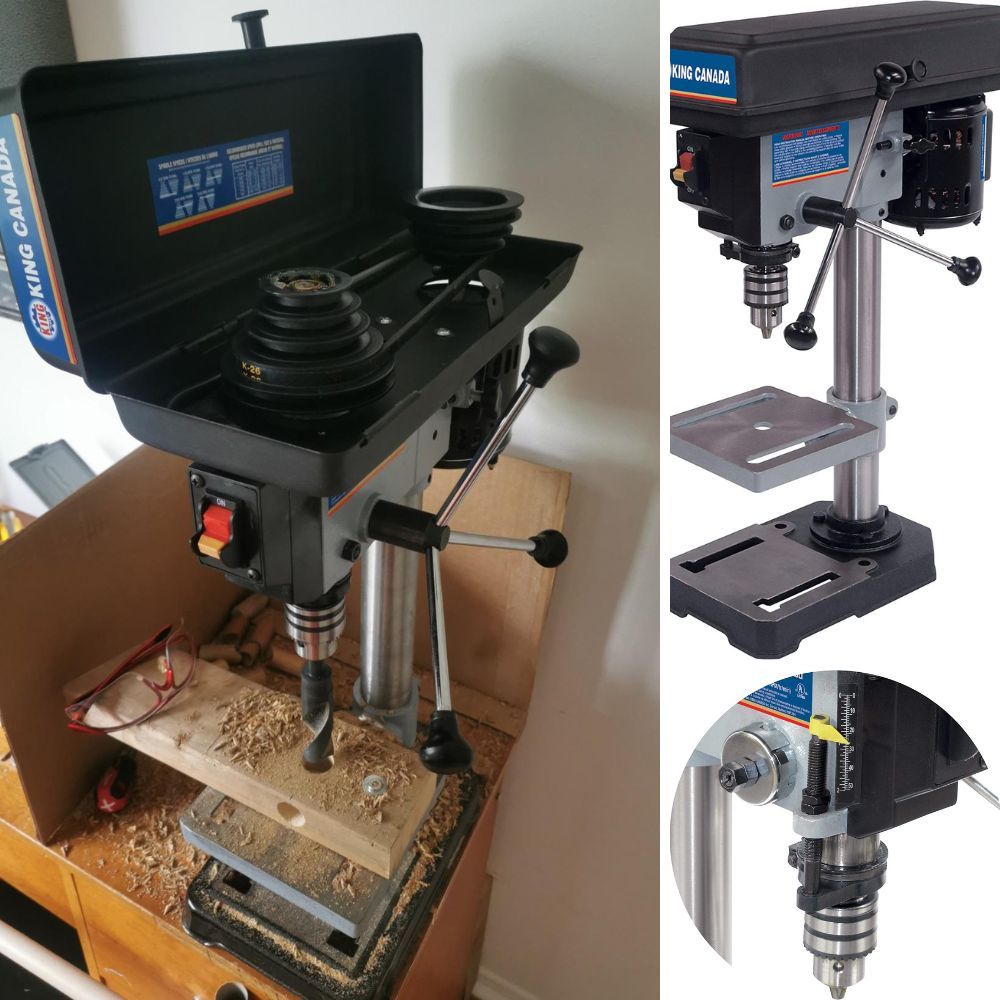

The King Canada KC-108N 8" Bench Drill Press is an essential tool for any do-it-yourselfer or professional. It features a powerful 2.5 Amp motor, which allows it to accept up to 1/2” shanked drill bits and have a 5 speed spindle RPM of 620-3100.

The heavy-duty cast-iron table and base ensures a stable working environment, while the positive depth stop allows for quick and easy adjustment. It also comes with a 1/2" drill chuck and key, making it a great choice for any workshop.

What You Should Know:

Not only is the King Canada KC-108N 8" Bench Drill Press a powerful and reliable tool, but it is also simple to use. Its 45-degree tilting table allows for angular drilling, while its spindle is supported by high quality ball bearings for increased durability.

It is also lightweight and easily portable, making it a great choice for any do-it-yourselfer or professional. So why wait? Get your own King Canada KC-108N 8" Bench Drill Press today!

Why We Love It:

The Dremel Drill Press Rotary Tool Workstation Stand with Wrench is the perfect tool for any DIY enthusiast. It’s a drill press, tool holder and flex shaft holder all in one.

It holds your tool in place for applications like sanding and buffing, and the telescoping flex shaft holder extends to any height between 16 and 29 inches. Plus, it can drill accurate perpendicular and angled holes.

It features articulating drill press that drills perpendicular and angled holes in 15-degree increments, up to 90 degrees horizontal. It also has spur and reamer tips for cleaner holes and provides a cleaner hole quality with reduced breakout.

The tool holder holds tool at 90 degrees horizontal for tasks such as polishing metal objects, sanding different shapes and grinding metal pieces.

What You Should Know:

The Dremel Drill Press Rotary Tool Workstation Stand with Wrench is the perfect choice for anyone who needs to drill holes with accuracy. It’s designed to help you get the job done quickly, easily and with precision. Plus, it’s really easy to use and will help you get the perfect results every time.

With its durable construction and quality materials, this tool is sure to last for years to come. So why wait? Get your own Dremel Drill Press Rotary Tool Workstation Stand with Wrench today!

KEEP DRILLING👇😀

FREQUENTLY ASKED QUESTION

Are you looking for a jet drill press but don't know where to start?

Finding the right jet drill press can be a daunting task. With so many different models and features to choose from, it can be hard to know which one is the best fit for your needs.

We've compiled a list of the most frequently asked questions about jet drill presses so you can make an informed decision and find the right jet drill press for you.

1.What rules should be followed when using a drill press?

When using a drill press, it is important to always wear eye protection, as the spinning drill bit can create metal shavings that can fly off and cause serious injury.

Additionally, it is important to use the proper drill bit for the material you are working with and to adjust the speed of the drill press to the appropriate level for the material. It is also important to make sure that the workpiece is securely clamped down and to keep hands away from the drill bit at all times. Finally, it is important to use the correct feed rate and to never force the drill bit into the material.

2.How do you change the speed on a jet drill press?

Changing the speed on a jet drill press is a relatively simple process. First, locate the speed control knob on the side of the drill press. Turn the knob to the desired speed. The speed will be indicated on the speed dial. Once the desired speed is set, press the start button to begin the drill.

3. What are the 4 major parts of the drill press?

The four major parts of a drill press are the base, column, table, and spindle. The base is the foundation of the drill press and provides stability and support. The column is attached to the base and holds the spindle, which is the part of the drill press that holds the drill bit. The table is attached to the column and is used to secure the workpiece in place during drilling. The spindle is the part of the drill press that rotates the drill bit and is powered by a motor.

4. What are the potential hazards involved with the use of the drill press?

The potential hazards involved with the use of a drill press include kickback, which can occur if the drill bit binds in the workpiece, and can cause the workpiece to be thrown back at the operator; flying debris and chips, which can be thrown away from the workpiece and cause injury; and electrical shock, which can occur if the drill press is not properly grounded. Additionally, the operator should always wear safety glasses and hearing protection when operating a drill press.

5. What are 10 things you should avoid doing when using a drill press?

1. Always wear safety glasses when using a drill press.

2. Make sure the drill press is securely mounted to a workbench for stability.

3. Ensure that the drill bit is securely fastened in the chuck before starting.

4. Make sure the drill press is set to the correct speed for the material and bit being used.

5. Use a center punch to mark the exact spot you want to drill.

6. Secure the material to the drill press table with clamps before drilling.

7. Make sure the drill bit is sharp and properly lubricated.

8. Slowly lower the bit into the material and let the drill press do the work.

9. Avoid forcing the bit into the material.

10. Always unplug the drill press before making any adjustments.

6. What is the most common safety violation when using the drill press?

The most common safety violation when using a drill press is failing to wear safety glasses. Eye protection is essential when operating a drill press, as flying debris and chips created by the drill bit can cause serious eye injury. Additionally, it is important to ensure that the drill bit is sharp and properly secured before use. Other safety precautions include keeping loose clothing, jewelry, and long hair away from the drill bit and making sure that the drill press is properly grounded.

7. What is the best speed for drill press?

The best speed for a drill press depends on the material you are drilling and the size of the drill bit you are using. Generally, the larger the drill bit, the slower the speed should be. For wood, a speed of around 2000 RPM is appropriate for most drill bits. For metal, a speed of around 800-1000 RPM is recommended. It is best to start with a low speed and gradually increase it until you find the best speed for your application.

8. What happens if drill speed is too low?

If the drill speed is too low, the drill bit won't cut through the material efficiently and may cause the bit to overheat. This can lead to premature wear of the drill bit, and can also cause the material to be damaged or warped from the heat generated by the drill bit. Additionally, a low drill speed can cause the drill bit to bind in the material, making it difficult to remove and potentially damaging the material.

9. What determines the RPM of the drill press?

The RPM of the drill press is determined by the motor speed and the gear ratio of the drive system. The motor speed is determined by the voltage and frequency of the power source, and the gear ratio is determined by the number of teeth on the drive gear and the driven gear. The RPM of the drill press can be adjusted by changing the gear ratio or by changing the voltage and frequency of the power source.

10. What is the most common causes of accidents that occur on a drilling machine?

The most common causes of accidents that occur on a drilling machine are operator error, lack of maintenance, faulty equipment, and improper use of safety guards. Operator error can include not following safety protocols, such as not wearing the proper safety equipment or not following the manufacturer's instructions.

Lack of maintenance can lead to worn or faulty parts that can cause the machine to malfunction. Faulty equipment can also lead to accidents, as can improper use of safety guards. It is important to always follow the manufacturer's instructions, wear the proper safety gear, and regularly maintain the machine to prevent accidents.

CONCLUSION

Jet drill presses are a great addition to any workshop, offering superior accuracy and reliability. With the wide variety of models available, you’ll be sure to find one that fits your needs and budget. From entry-level models to professional-grade machines, Jet has a drill press that’s perfect for every user.

So if you’re looking for a drill press that offers exceptional performance and long-lasting durability, look no further than Jet! With their reliable products and top-notch customer service, Jet is sure to provide you with the perfect drill press for all your projects.