Are you looking for a way to become an expert at cutting aluminum with a miter saw? Look no further than our list of 7 easy steps to help you become a pro! With our tips and tricks, you'll be slicing through aluminum like a hot knife through butter!

Are you ready to take your metalworking skills to the next level? You can do just that with a miter saw and the right set of tools. With the right techniques, you can easily cut aluminum with a miter saw like a pro.

The first step is to make sure you have the right saw. A miter saw is designed to make precise, angled cuts, and is ideal for cutting aluminum. You’ll also need a jigsaw, a drill, and a set of clamps. Make sure you have a sharp blade for your saw, as this will make the job much easier.

Next, you’ll need to measure and mark your aluminum. Use a straight edge and a measuring tape to make sure your cuts are accurate. Once you’ve marked the aluminum, clamp it securely to your workbench.

Now you’re ready to start cutting. Start with a shallow cut and gradually increase the depth. Make sure you’re using a steady, even motion and don’t apply too much pressure. Once you’ve made the initial cut, you can use a jigsaw to finish the job.

Finally, you’ll need to clean up your edges. Use a file or sandpaper to smooth out any rough edges. Once you’ve finished, you’ll have a perfectly cut piece of aluminum.

With these 7 easy steps, you’ll be able to cut aluminum with a miter saw like a pro. You’ll be able to make precise, accurate cuts with ease. And you’ll be able to create amazing projects with your new metalworking skills. So don’t wait any longer – get started today and unlock the potential of your miter saw!

When you need to make precise cuts in aluminum, a miter saw is the perfect tool for the job. But with so many different brands and types of miter saws available, it can be hard to know which one will give you the best value for your money.

Our team of experts has read thousands of reviews on Amazon to find the best miter saws for cutting aluminum. We've done all the hard work so that you can easily find and purchase the perfect saw for your project.

No more guesswork or wasted money - just precision cuts in aluminum with ease! Check out our reviews of the best miter saws today and get started on your next project!

1.Why We Love It:

Evolution Power Tools EVOSAW380-15 in Steel Chop Saw is the ideal tool for anyone who needs to cut metals like steel plate, square tube, angle iron, pipe, tube, and metal roofing quickly and easily.

With a 15A motor and a 1” arbor, you can instantly get a workable finish with no coolant required. Plus, it cuts cold and doesn’t produce any heat, burrs, or sparks.

What You Should Know:

The EVOSAW380-15 steel chop saw is an upgraded version of the discontinued Steelsaw2 cut-off saw and comes with a 3 year warranty.

It’s easy to use and can cut through rectangle and square tubes up to 3” by 4-3/8” and 5-1/8” round tube, as well as 4-3/4” square and 4-1/8” round tube. Plus, it can handle a maximum mild steel plate of 3/4”.

Get your own Evolution Power Tools EVOSAW380-15 in Steel Chop Saw today and start cutting metals like a pro!

2.Why We Love It:

The Makita LS1219L 12" Dual-Bevel Sliding Compound Miter Saw with Laser is the perfect saw for metal cutting and other tough jobs. This saw features an innovative direct-drive gearbox and guard system that is engineered for increased vertical cutting capacity and will make 15” crosscuts at 90 degrees.

It has a unique 2-steel rail sliding system that offers a reduced footprint for operation flush against a wall and a bevel lock located in the front of the saw for easy access and quick adjustments.

Plus, it is powered by a 15 amp direct drive motor with soft start and an electric brake for added convenience.

What You Should Know:

The Makita LS1219L is a powerful saw that has a range of 0° to 60° left and right miter angles, with positive stops at 0°, 15°, 22.5°, 31.6°, 45° and 60° (left or right). It also has electronic speed control that maintains constant speed under load for smoother, higher-quality cuts.

This saw is perfect for anyone looking for precision and accuracy when cutting metal and other tough materials. Plus, its compact size allows it to be easily stored and moved, making it perfect for any workspace. So why wait? Get your own Makita LS1219L today!

3.Why We Love It:

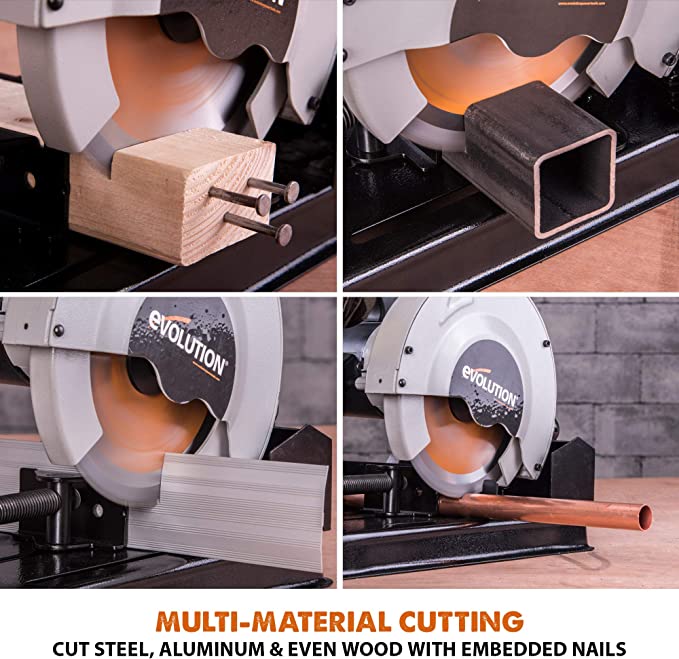

The Evolution RAGE 4, 7-1/4-Inch, TCT, Multipurpose Chop Saw is a must-have for any tradesman. This award winning machine is capable of cutting steel, aluminum, wood with nails in, and plastic.

It can also cut through 2 by 4 planed lumber and reclaimed lumber with nails and screws. Plus, it produces virtually no heat, burrs, or sparks when cutting aluminum workpieces.

What You Should Know:

This powerful saw is also a great tool for cutting plastic such as acrylic and drainage tubing, as well as for cutting down threaded rod to an exact size.

With its powerful motor and advanced cutting technology, the RAGE 4 provides accurate and fast cutting.

It has an ergonomic design for long lasting comfort, and comes with a selection of blades for easy and efficient cutting. So why wait? Get the Evolution RAGE 4 today and get the job done!

4.Why We Love It:

Goplus Table Saw, 10-Inch 15-Amp Portable Table Saw, 36T Blade, is the perfect tool for tackling all of your cutting needs.

It features a powerful 15 Amp motor that delivers 5,000 RPM cutting performance, a coated aluminum tabletop with 26" rip capacity, and a 36T carbide-tipped blade with a transparent guard and riving knife to protect you from accidental hurts and flying chips.

It also has a double bevel cutting from 0-45°, and a large hand wheel to control the blade lifting.

What You Should Know:

Goplus Table Saw is the ideal choice for cutting speed and accuracy. Its self-aligning rip fence with parallel guide on both sides assists with more precise and stable cutting without any wobbling.

The sliding miter gauge can be adjusted from -45° to 45° for cross cutting, and the adjustable height effectively prevents table from rollover during cutting. If you're looking for a quality table saw for all your woodworking needs, the Goplus Table Saw is just the one for you!

Goplus Table Saw

Aluminum Table, Benchtop Table Saw with Metal Stand, Sliding Miter Gauge

5.Why We Love It:

The Makita LC1230 12" Metal Cutting Saw is the perfect tool for tackling jobs that require precise and accurate cuts. Featuring a carbide-tipped blade that lasts up to 50x longer than abrasive wheels and can cut clean, accurate and virtually burr-free, this saw is the ideal choice for any metal cutting job.

Plus, it has a quick release vise for secure material retention and fast, repeated cut-offs, a lock-off button for user convenience, and a quick release support fence that adjusts 0-45° for miter cutting.

What You Should Know:

The Makita LC1230 12" Metal Cutting Saw is perfect for cutting light pipe, angle iron, tubing, conduit, and channel four times faster than abrasive cut-off saws. It also includes a long-lasting carbide-tipped blade for clean and accurate cutting, and comes with a wheel change wrench for easy blade changes.

Plus, it has a D-handle for comfort, a trigger lock for safety, and a shaft lock for maximum efficiency. So why wait? Invest in the Makita LC1230 12" Metal Cutting Saw today and get the job done right!

Miter Saw Cutting Aluminum FAQs

Do you need a miter saw for cutting aluminum, but don't know which one to choose?

Finding the right miter saw for cutting aluminum can be a challenge. With so many different brands and types out there, it can be hard to know which one is best for your needs. You want a miter saw that is strong enough to cut through aluminum, but you also want one that is easy to use and won't break the bank.

We've compiled a list of the most frequently asked questions about miter saws for cutting aluminum so you can know more about these saws and make an informed decision.

1.How do you cut an angle with an aluminum miter saw?

Using an aluminum miter saw is a great way to make precise angled cuts in aluminum. To do this, you will need to adjust the miter saw blade to the desired angle. This can be done by setting the miter saw's angle adjustment knob to the angle you need. Once the angle is set, you can then use the miter saw to make the cut. Be sure to use a blade specifically designed for cutting aluminum for best results.

2. What kind of saw do you use to cut aluminum?

For cutting aluminum, you should use a saw with a fine-toothed blade. The most common type of saw used for this is a miter saw. It has a blade with very small teeth that can make precise cuts in aluminum without leaving jagged edges. Alternatively, you can also use a jigsaw with a fine-toothed blade, or a circular saw with a special aluminum-cutting blade.

3. What do you need to do when cutting aluminum?

When cutting aluminum, it's important to use the right tools and techniques. You'll need a saw with a fine-toothed blade specifically designed for cutting aluminum, as well as lubrication to keep the blade cool and reduce friction. Additionally, you should use a slow, steady cutting motion and use a clamp to hold the aluminum in place while cutting. Finally, be sure to wear safety glasses to protect your eyes from flying metal chips.

4. Which cutting process is better for cutting aluminum?

The best cutting process for cutting aluminum depends on the specific application and the desired results. Generally, the most common cutting processes used for aluminum are laser cutting, plasma cutting, and waterjet cutting. Each of these processes has its own advantages and disadvantages, and the best choice will depend on the specific application. Laser cutting is ideal for intricate shapes and tight tolerances, while plasma cutting is better for thicker materials and faster cutting speeds. Waterjet cutting is great for cutting intricate shapes with high precision and no heat-affected zone.

5. Is it better to cut aluminum fast or slow?

It is generally better to cut aluminum slowly in order to reduce heat buildup and minimize the risk of warping or other damage. Aluminum is a soft metal, so it is relatively easy to cut with a saw or other cutting tool. When cutting aluminum, it is important to use a blade specifically designed for cutting aluminum, as regular steel blades can cause excessive heat buildup and damage the aluminum. Additionally, it is important to use a lubricant such as oil or wax to help reduce friction and heat buildup.

6. What is the best blade to cut aluminum?

The best blade to cut aluminum is a carbide-tipped blade. Carbide-tipped blades are designed specifically for cutting aluminum and other non-ferrous metals. They are made of a combination of tungsten carbide and cobalt, which makes them extremely durable and able to withstand high temperatures. In addition, they have a special tooth geometry that helps reduce friction and heat buildup while cutting aluminum, which helps prolong the life of the blade.

7. What is the best way to cut aluminum angle?

The best way to cut aluminum angle is by using a chop saw with a special blade designed for cutting metal. When cutting aluminum angle, it is important to use a blade with a high tooth count to reduce the risk of the material fracturing or becoming damaged. Additionally, it is important to use a lubricant such as cutting oil when cutting aluminum angle to reduce friction and heat buildup, which can cause the material to warp.

8. Can you use mitre saw to cut metal?

No, a mitre saw is not suitable for cutting metal. Mitre saws are designed for cutting wood and other materials such as plastic, but they are not suitable for cutting metal. For cutting metal, you should use a metal-cutting saw such as a chop saw, band saw, or circular saw with a metal-cutting blade.

9. What is the cutting speed for aluminum?

The cutting speed for aluminum depends on the type of aluminum, the tool being used, the cutting conditions, and the desired surface finish. Generally speaking, cutting speeds for aluminum range from 80 to 400 feet per minute (fpm). For example, when using a high-speed steel tool, the cutting speed for 6061-T6 aluminum is typically around 200 fpm.

10. What speed should you cut aluminum?

When cutting aluminum, you should use a saw blade with a speed of at least 2,500 RPM. The higher the speed, the smoother the cut. Additionally, use a lubricant, such as a cutting oil or wax, to reduce friction and heat build-up. This will help to extend the life of your saw blade and improve the quality of the cut.

Conclusion:

Cutting aluminum with a miter saw doesn't have to be a daunting task. By following the 7 simple steps outlined in this article, you can get the job done quickly and accurately.

From choosing the right blade to cleaning up the debris, these tips will ensure that your aluminum cutting project goes smoothly.

Now that you know the basics, you can get started on your aluminum project with confidence. Just remember to keep safety in mind and wear the proper protective gear, and you'll be ready to cut aluminum like a pro in no time!